digital

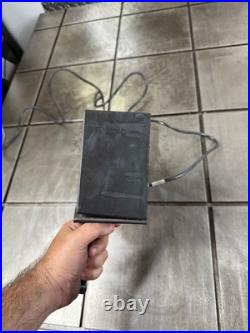

SONY LH33-3S 3 axis DRO Digital Read Out Tested #7512

SONY LH33-3S 3 axis DRO Digital Read Out Tested #7512.

DRO Display 3Axis Digital Read Out Lathe Ruler Scale 150&300&900mm Kit #A6-12

Item contains:One item. We have a lot of products and only show a small number of products on the website. We offer the state of the art products, which include motors, drives, switch, modules, CUP, electronic accessories, motherboards, custom built computers, refurbished desktops, refurbished laptops, monitors, printers, desktop & laptop accessories/parts & much more! We will respond to you very promptly. Please contact me through emails to get a much better price. These charges are the buyers responsibility. We will answer your questions in 48 hours, deal with one time every day. Saturday and Sunday is our holiday, If you send me message on Saturday and Sunday, we can’t reply you in time. But please no worries and we will reply you on next Monday immediately.

3 Axis DRO LCD Screen Metal Shell Digital Readout Display for Bridgeport Mill

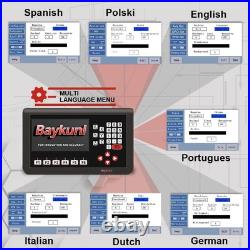

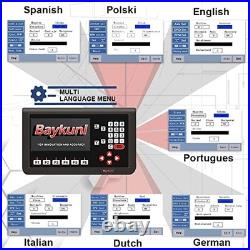

? Order Details 3 axis Dro Digital Readout and 3 pcs normal size magnetic scale, complete dro kits??? It is a mutlifunctional 3 axis DRO Metal Shell Digital Readout can be widely use on Milling Machine? Lathe Machine and Grinding machines??? The magnetic scale choose from 50-1000mm travel length, for over 1020mm, pls contatct us.

2/3Axis Digital Readout TTL Linear Scale DRO Encoder For Milling Lathe cutting

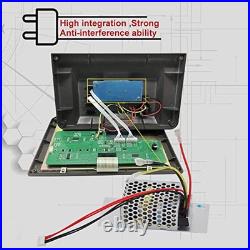

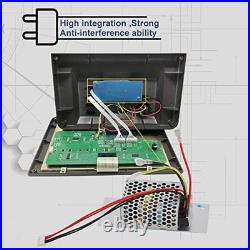

1 x Accessory kit include scale cover, L connecting bracket, scale cover, screw bag and so on. 1 x English User Manual. Applicable for the machine such as millers, lathes, boring machines, grinding machines and EDM, etc.. Read all the instructions in the manual carefully before used and strictly follow them. Keep the manual for future references. 29517065mm (11.6″6.7″2.56). 8 bit LED High-definition nixie tube mm/inch mode, ABS/INC coordinate conversion, zero clearing, reset, liner error compensation, center of 1/2, R arc function(RAC), vibration filtering, digital filtering, sleep mode, divide circle evenly (PCD), 200 sets sub datum function, drilling of oblique line, taper measurement, Anti-interference resistance, high speed, high resistance to vibration. Linear drilling PCD function R function Smooth R function The simple R function Chambering (applicable to: Milling machine, Boring machine) Tool conpensation Machining of oblique plane Calculator, etc. We also supply 1um/0.001mm resolution linear scale, please leave a message , We will give you the most favorable price. Q1: Are the length 100mm, 150mm, 200mm, 250mm…. 1500mm travel length or total? Answer : all are travel length. Q2: If I need 200mm, 450mm scales with 2axis digital readout, how should i do? Q3: What does the dro measure to? Answer : measure to 0.001mm, 0.0001inch (1inch=25.4mm). Q4: If I need a scale like 255mm, can you offer it? Answer : 250mm is enough, its measuring range can reach up to 270mm, so you can use if you need to measure 255mm. Q5: Can I cut the scales by myself? Answer : Technically NO, it maybe unavailable after cutting. Q6: Do you have English user manual? Answer : yes, it comes with the dro box. Q7: Do you have other cheaper types, such as measure to 0.005mm? Answer : Yes, 0.005mm (0.0002) is available. Q8: Is it easy to install these scales and dro? Answer : Please must check the scale pin definition (1,2,3,4,5,6,7,8,9), which is very important!! Q10: How to switch between milling machine lathe grinding machines.

Large 7inch LCD Screen TTL 2 Axis Digital Readout Display DRO RPM Mill Lathe

? Order Details 2 axis Dro Digital Readout and 2 pcs normal size magnetic scale, complete dro kits??? It is a mutlifunctional 2 axis DRO Metal Shell Digital Readout can be widely use on Milling Machine? Lathe Machine and Grinding machines??? The magnetic scale choose from 50-1000mm travel length, for over 1020mm, pls contatct us. The travel length optional (LO): 170mm, 220mm, 270mm, 320mm, 370mm, 420mm, 470mm, 520mm, 570mm, 620mm, 670mm, 720mm, 770mm, 820mm, 870mm, 920mm, 970mm, 1020mm??? Please leave a massage what travel length do you request Order included:? 1 piece 2 axis DRO? 2 piece 5um magnetic scale IP67 sealing protection? Packing included dust cover, bracket, American standard power cable and operation manual of mganetic scale /digital readout? 4pcs magnetic encoder scale, each with 3m cable, brackets, screws, mounting plate, brackets, operation manual? Description:? Function:? Zeroing? Date Recovery? Input Coordinate? Metric /British Units? Power off memory function? Encoder setting? Resolution setting? Linear compensation? Counting? Direction setting? ABS/INC? Coordinate 200 sets? SDM Coordinate? REF? Caculator? None-Linear compensation? 1/2 Function? Sleeping function? Pld Function? Tools offsets? PLD functions? Simple R function? Smooth R function? Rectangle Chambering Function? Taper Measuring? Radius / Diameter conversion? Y+Z function? Digital Flitering Function? Preview Drawing function? Tool loation displaying? Axis summing (same direction)? Magnetic scale : Resolution :5um Width : 28mm Output signal :RS422 Max speeding :150M/MIN Supply Current.

High Precision 5 Axis Digital Readout Dro High Cost Performance New zx

High Cost Performance High Precision Dro 5 Axis Readout Digital New. Chinese or English LCD display with the function of automatically midsplit. The function of switching from metric system to British system. The function of switching from absolute counting to relative counting. 4.1000 group of zero memory function. Function calculator computation function. Arc surface processing function. Error compensation of machine tool function. 1 axis, 2 axis, 3 axis. 8 LED digital tube display, high-grade LCD. >100 meters per minute. Chinese or English display to cater to different customers. E2PROM power off memory, avoid battery changes and maintenance, 10 years memory. Able to use 1million times, best guarantee, ultra-thin, anti-interference, high speed and vibration resistance. 1u reading head(big). 5u reading head(big). Magnetic grating(include aluminium rod). Wed, 07 May 2025 16:53:56 GMT 638822624366590992 0700738A5C161B1B.

3Axis 6 & 12 &20 Display Digital ReadOut DRO Scale 5um TTL CNC Milling #A6

Item contains:One item. We have a lot of products and only show a small number of products on the website. We offer the state of the art products, which include motors, drives, switch, modules, CUP, electronic accessories, motherboards, custom built computers, refurbished desktops, refurbished laptops, monitors, printers, desktop & laptop accessories/parts & much more! We will respond to you very promptly. Please contact me through emails to get a much better price. These charges are the buyers responsibility. We will answer your questions in 48 hours, deal with one time every day. Saturday and Sunday is our holiday, If you send me message on Saturday and Sunday, we can’t reply you in time. But please no worries and we will reply you on next Monday immediately.

Single / One 1 Axis Simple Digital Readout DRO fast shipping #A7

Item contains:One item. For such kind of the items, the price and quantity change very fast. So the price here is inaccurate and please make offer or contact me for the correct price. We have a lot of products and only show a small number of products on the website. If you have any question, please contact me directly. Instead of opening CASE. That brings us very bad effect and can’t solve any problem. We will give big discount for the future business. International buyers please note. If you receive a defective item, you need to return or discount. Or sent you a replacement if you need. US, UK, CA, AU. We will answer your question in 48 hours, deal with one time every day. Saturday and Sunday is our holiday, If you send me message on Saturday and Sunday, we can’t reply you in time. But please no worries and we will reply you on next Monday immediately.

Single Axis Digital Readout Dro Best Quality High Cost Performance qu

Best Quality Digital Readout Dro Single Axis High Cost Performance. Chinese or English LCD display with the function of automatically midsplit. The function of switching from metric system to British system. The function of switching from absolute counting to relative counting. 4.1000 group of zero memory function. Function calculator computation function. Arc surface processing function. Error compensation of machine tool function. 1 axis, 2 axis, 3 axis. 8 LED digital tube display, high-grade LCD. >100 meters per minute. Chinese or English display to cater to different customers. E2PROM power off memory, avoid battery changes and maintenance, 10 years memory. Able to use 1million times, best guarantee, ultra-thin, anti-interference, high speed and vibration resistance. 1u reading head(big). 5u reading head(big). Magnetic grating(include aluminium rod). Sat, 03 May 2025 09:26:58 GMT 638818900180184682 0700738A5C161B1B.